McCLOSKEY ESS-300 | MOBILE MACHINERY FIRE SUPPRESSION

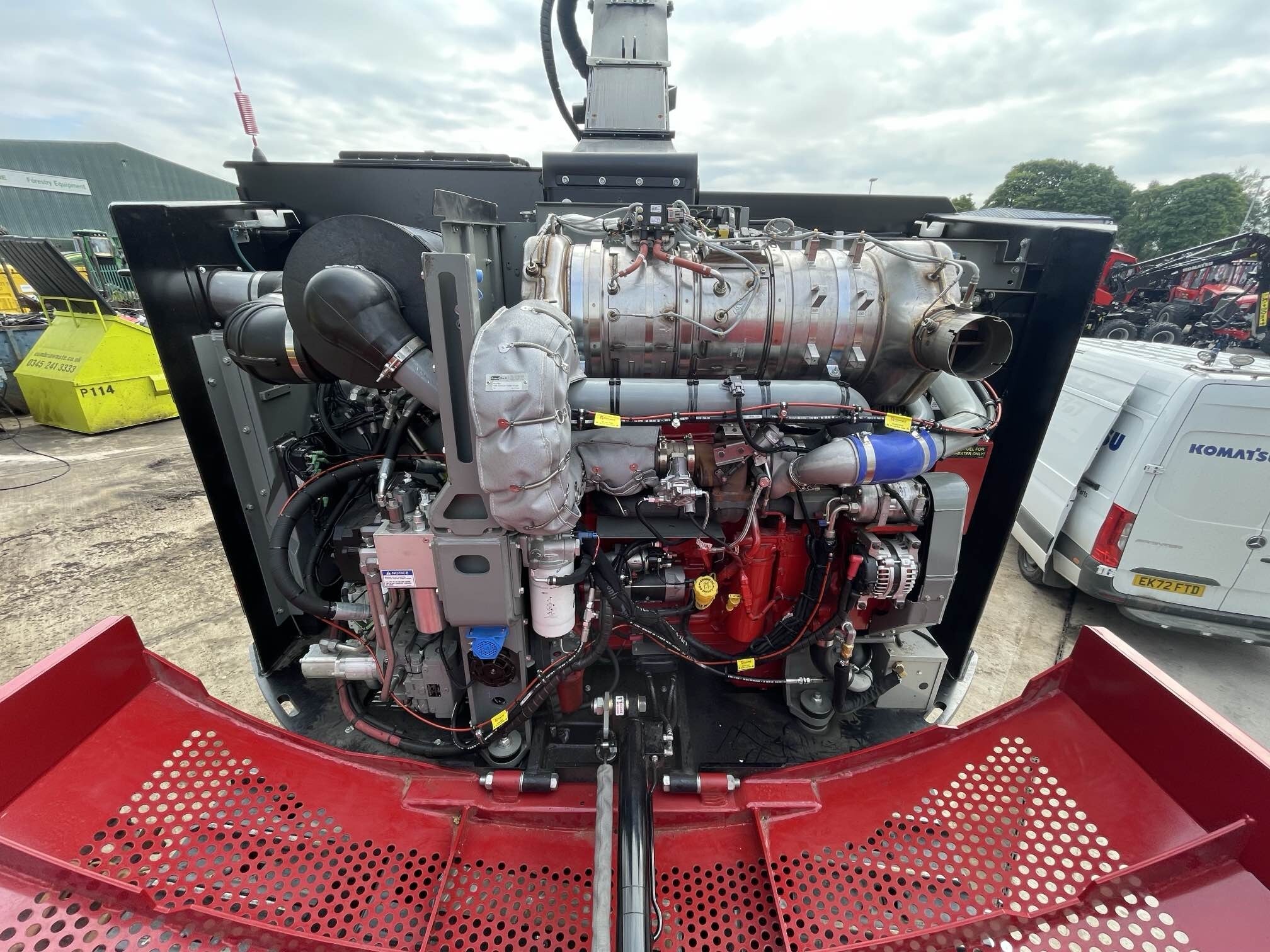

We recently installed our Dual Agent Automatic Fire Suppression System on a McCloskey ESS-300 Mobile Shredder, delivering critical fire protection for high-risk waste and recycling operations.

How Fireward’s Dual Agent System Works

This system uses dry powder for rapid flame knockdown and wet chemical for a prolonged cooling effect on superheated components. A Pneumatic Detection Tube bursts when exposed to flame, releasing pressure in the cylinder and discharging the suppression agents through strategically placed nozzles in the engine bay.

System highlights:

-

Dry Powder – Rapid flame knockdown

-

Wet Chemical – Prolonged cooling of superheated components

-

Pneumatic Detection – Activates system when exposed to fire

-

Indirect Release System – Agents discharged through nozzles targeting key risk areas

Additional Features:

Battery Isolator – Disconnects electrical supply to minimise fire risk

Equipment Shutdown – Halts machine operation when activated

Manual Actuator – Enables manual system discharge in emergencies

(WATCH) How does the system work?

Fire Risks in Mobile Shredders

The McCloskey ESS-300 operates in dusty, hot conditions with flammable waste material, increasing the chance of fire. A reliable fire suppression system is essential for reducing downtime and protecting both the operator and the machine.

Built-in Fire Protection for Mobile Shredders

Fireward’s automatic fire suppression systems provide robust protection where it’s needed most — on the front lines of waste processing.

Protect your equipment with Fireward’s automatic fire suppression systems.

Fireward, Protecting People and Assets 24/7.

To find out more about Fireward’s Automatic Fire Suppression systems, get in touch by calling 0800 151 0249 or email at: sales@fireward.co.uk.

You May Also Like

These Related Stories

Komatsu Timber Pro 745

Volvo EC750