Why Static Plant Fire Protection Gets Overlooked

By Ben Robinson on May 22, 2025 11:50:20 AM

Fire safety for mobile plant machinery is well understood. But static equipment—like balers, compactors, conveyors, and electrical control panels—is often left unprotected until it’s too late. These machines may not move, but that doesn’t mean they’re low risk. In fact, they’re some of the most common sources of fire in waste & recycling, and manufacturing environments.

The Overlooked Fire Risk of Balers and Static Machinery

Balers are one of the highest-risk static machines on any site. Compressing paper, cardboard, plastics, and other highly combustible materials generates heat and friction. Combine that with hydraulic fluid and electrical components, and you’ve got all the ingredients for a serious fire.

Dust accumulation, motor overheating, and oil leaks are equally dangerous across other static plant. Because these machines often run in the background, unattended for long hours—fires can break out and spread before anyone even notices.

How Fireward’s Dual Agent System Works

Our Dual Agent automatic fire suppression system combines dry powder and wet chemical agent for a comprehensive response to multiple fire types:

- Dry Powder rapidly knocks down flames in enclosed and hard-to-reach areas.

- Wet Chemical Agent cools identified heat spots with the nozzles aimed at those areas, reducing the risk of reflash in hydraulic or oil-based fires.

This makes Dual Agent the ideal choice for high-risk static machines like balers, where both Class A (combustibles) and Class B (flammable liquids) risks are present.

Watch our system detect and suppress a fire on a shredder

Pneumatic Detection: Faster and Simpler

Some suppression systems rely on linear electronic detection cables, which activate only when an electrical signal is triggered—usually once the fire is well developed. In real terms, it could take almost 40 seconds longer, that delay can be the difference between saving a machine and losing it.

See for yourself in this video:

Fireward systems use pneumatic detection, which doesn’t rely on power. Instead, the heat from a fire causes a pressurised detection tube to burst, instantly releasing pressure that triggers the suppression system. The result? Near-instant activation—often significantly faster than electronic systems—with no false alarms, no complex wiring, and minimal maintenance.

Fire Risks in Static Plant

Static equipment like balers, shredders, and conveyors are frequently exposed to dust, debris, and high operating temperatures. Fires often start from unseen electrical faults or friction within compacted material, making fast detection and suppression essential to prevent large-scale damage.

Built-in Fire Protection for Static Plant

Fireward’s systems are tailored to the environment. Whether it’s protecting the motor housing on a baler or the control cabinet on a conveyor line, our solutions are built to detect fire early and suppress it quickly—without human intervention.

Additional Features

Machine Shutdown – Automatically switches off equipment to prevent fire escalation

Manual Actuator – Gives on-site personnel full manual control if needed

Sounder Beacon – Provides a loud and visible alert on system activation, improving site awareness

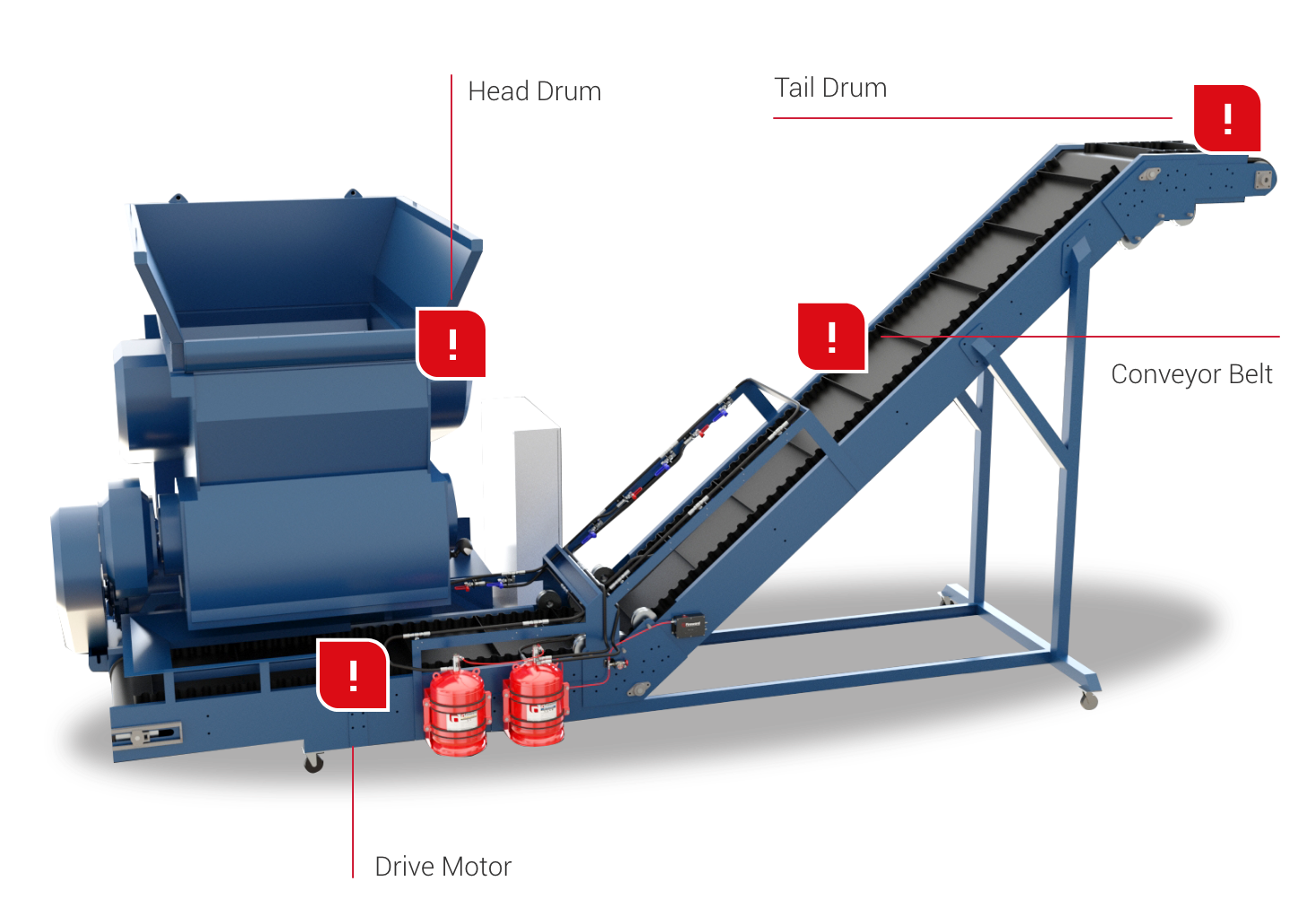

Here is an example of some of our work on static plant

If you are looking to get a Fireward system to protect your valuable assets and minimise cost and the potentially extensive downtime a fire can cause, reach out to our team or click the button below to receive a quote.

Fireward, Protecting People and Assets 24/7.

To find out more about Fireward’s Automatic Fire Suppression systems, call 0800 151 0249 or email at: sales@fireward.co.uk.

You May Also Like

These Related Stories

£12.7 Million in Assets Protected from Fire in 2025

Fire, Suppressed. Asset, Protected.